Heyco® Liquid Tight Cordgrips Overview

Competitor Cross Reference

% can be used as a wildcard in search

Heyco® Multi-Hole Selector Tool

Heyco® Multi-Hole Selector Tool

Heyco-Tite Liquid Tight Cordgrips Liquid Tight Threaded, Threaded Vent and Snap-In Vent Plugs

Heyco-Tite Liquid Tight Cordgrips Liquid Tight Threaded, Threaded Vent and Snap-In Vent Plugs

Heyco® V-0 Nylon and Metal Liquid Tight Cordgrips Brochure

Heyco® V-0 Nylon and Metal Liquid Tight Cordgrips Brochure

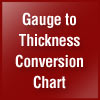

Sheet Metal Gauge to Thickness Conversion Chart

Sheet Metal Gauge to Thickness Conversion Chart

Nylon Cordgrips

Heyco® Multi-Hole Selector Tool

Heyco® Multi-Hole Selector Tool

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Straight-Thru, NPT Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips for Pre-assembled Cables

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Straight-Thru, PG Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Straight-Thru, Metric Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Pigtail, NPT Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Pigtail, PG Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Pigtail, Metric Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Right Angle, NPT Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Right Angle, PG Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Right Angle, Metric Hubs

No Locknut Required!

No Locknut Required!Heyco®-Tite Snap-In-2® Liquid Tight Cordgrips Straight-Thru, Snap-In Hubs

No Locknut Required!

No Locknut Required!Heyco®-Tite Snap-In-2® Liquid Tight Cordgrips Pigtail, Snap-In Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Multi-Hole for Smaller Conductors

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips Multi-Hole for Larger Conductors

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Break-Thru™ Cordgrips

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Romex® and Other Oval Hole Connectors

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips in Halogen Free V-0 Nylon, Straight-Thru, NPT Hubs

No O-Ring Required!

No O-Ring Required!Heyco®-Tite Liquid Tight Cordgrips in Halogen Free V-0 Nylon, Straight-Thru, PG & Metric Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Straight-Thru, NPT Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Straight-Thru, NPT Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Straight-Thru, PG Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Straight-Thru, PG Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Pigtail, NPT Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Pigtail, NPT Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Pigtail, PG Hubs

Heyco® Original Series-35 Liquid Tight Cordgrips Pigtail, PG Hubs

Heyco® Liquid Tight Strain Relief Bushings

Heyco® Liquid Tight Strain Relief Bushings

Heyco® Liquid Tight Cordgrips Torque Chart

Heyco® Liquid Tight Cordgrips Torque Chart

Stainless Steel Cordgrips

HEYbrid™ Stainless Steel Liquid Tight Cordgrips - Straight-Thru, NPT Hubs

HEYbrid™ Stainless Steel Liquid Tight Cordgrips - Straight-Thru, NPT Hubs

HEYbrid™ Stainless Steel Liquid Tight Cordgrips - PG Hubs

HEYbrid™ Stainless Steel Liquid Tight Cordgrips - PG Hubs

HEYbrid™ Stainless Steel Liquid Tight Cordgrips - Metric Hubs

HEYbrid™ Stainless Steel Liquid Tight Cordgrips - Metric Hubs

Heyco® Steel Cordgrips Torque Chart

Heyco® Steel Cordgrips Torque Chart

Plated Steel Cordgrips

Heyco®-Tite Metallic Liquid Tight Cordgrips - NPT Hubs

Heyco®-Tite Metallic Liquid Tight Cordgrips - NPT Hubs

Aluminum Cordgrips

Heyco®-Tite Aluminum Liquid Tight Cordgrips - NPT ¼ thru ½

Heyco®-Tite Aluminum Liquid Tight Cordgrips - NPT ¼ thru ½

Heyco®-Tite Aluminum Liquid Tight Cordgrips - NPT ¾ thru 1-1/4

Heyco®-Tite Aluminum Liquid Tight Cordgrips - NPT ¾ thru 1-1/4

Heyco®-Tite Aluminum Liquid Tight Cordgrips - NPT 1-1/2 thru 2

Heyco®-Tite Aluminum Liquid Tight Cordgrips - NPT 1-1/2 thru 2

Heyco®-Tite Cast Aluminum Liquid Tight Cordgrips - NPT 2 ½

Heyco®-Tite Cast Aluminum Liquid Tight Cordgrips - NPT 2 ½ thru 3

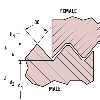

Heyco®-Tite Aluminum Liquid Tight Cordgrips - Right Angle

Heyco®-Tite Aluminum Liquid Tight Cordgrips - Right Angle

Heyco® Aluminum Cordgrips Torque Chart

Heyco® Aluminum Cordgrips Torque Chart

Nickel-plated Brass Cordgrips

Heyco®-Tite Brass Liquid Tight Cordgrips - NPT Hubs

Heyco®-Tite Brass Liquid Tight Cordgrips - NPT Hubs

Heyco®-Tite Brass Liquid Tight Cordgrips - NPT Hubs, High Temperature

Heyco®-Tite Brass Liquid Tight Cordgrips - NPT Hubs, High Temperature

Heyco®-Tite Brass Liquid Tight Cordgrips - PG Hubs

Heyco®-Tite Brass Liquid Tight Cordgrips - PG Hubs

Heyco®-Tite Brass Liquid Tight Cordgrips - PG Hubs, High Temperature

Heyco®-Tite Brass Liquid Tight Cordgrips - PG Hubs, High Temperature

Heyco®-Tite Brass Liquid Tight Cordgrips - Metric Hubs

Heyco®-Tite Brass Liquid Tight Cordgrips - Metric Hubs

Heyco®-Tite Brass Liquid Tight Cordgrips - Metric Hubs, High Temperature

Heyco®-Tite Brass Liquid Tight Cordgrips - Metric Hubs, High Temperature

Heyco®-Tite Brass Liquid Tight Cordgrips - Metric Hubs - Explosion Proof

Heyco®-Tite Brass Liquid Tight Cordgrips - Metric Hubs - Explosion Proof

Heyco®-Tite Brass Locking Plugs, Metric Hubs

Heyco®-Tite Brass Locking Plugs, Metric Hubs

HEYBrid™ Brass/Nylon Liquid Tight Cordgrips, Metric Hubs

HEYBrid™ Brass/Nylon Liquid Tight Cordgrips, Metric Hubs

Heyco®-Tite Brass Liquid Tight Clamping Cordgrips

Heyco®-Tite Brass Liquid Tight Clamping Cordgrips

Heyco®-Tite EMC Brass Liquid Tight Cordgrips, PG Hubs

Heyco®-Tite EMC Brass Liquid Tight Cordgrips, PG Hubs

Heyco®-Tite EMC Brass Liquid Tight Cordgrips, Metric Hubs

Heyco®-Tite EMC Brass Liquid Tight Cordgrips, Metric Hubs

Heyco®-Tite EMC-2 Brass Liquid Tight Cordgrips

Heyco®-Tite EMC-2 Brass Liquid Tight Cordgrips

Heyco-Tite Nickel-Plated Brass EMC Locknuts

Heyco-Tite Nickel-Plated Brass EMC Locknuts

Heyco®-Tite Brass Lazy Bend Liquid Tight Cordgrips

Heyco®-Tite Brass Lazy Bend Liquid Tight CordgripsEPDM Nozzle

Heyco®-Tite Brass Lazy Bend Liquid Tight Cordgrips

Heyco®-Tite Brass Lazy Bend Liquid Tight CordgripsStainless Steel Nozzle

Heyco®-Tite Brass Profile Liquid Tight Cordgrips

Heyco®-Tite Brass Profile Liquid Tight Cordgrips

Heyco® Brass Cordgrips Torque Chart

Heyco® Brass Cordgrips Torque Chart

Locknuts

Heyco® Nickel-Plated Brass Locknuts Metric Thread

Heyco® Nickel-Plated Brass Locknuts Metric Thread

Heyco® Nylon Locknuts NPT Thread

Heyco® Nylon Locknuts NPT Thread

Heyco® Nylon Locknuts PG Thread

Heyco® Nylon Locknuts PG Thread

Heyco® Nylon Locknuts Metric Thread

Heyco® Nylon Locknuts Metric Thread

Heyco-Tite Nickel-Plated Brass EMC Locknuts

Heyco-Tite Nickel-Plated Brass EMC Locknuts

HEYClean® Nickel-Plated Brass Drain Plug Locknuts

HEYClean® Nickel-Plated Brass Drain Plug Locknuts

Heyco® Stamped Steel and Zinc Die-cast Locknuts NPT Thread

Heyco® Stamped Steel and Zinc Die-cast Locknuts NPT Thread

Heyco® Nickel-Plated Brass Locknuts PG Thread

Heyco® Nickel-Plated Brass Locknuts PG Thread

Accessories

Cross Reference from the LTB's and KOS-LT's to HEYCo-molded Liquid Tight Break-Thru Plugs (LTBP's)

Cross Reference from the LTB's and KOS-LT's to HEYCo-molded Liquid Tight Break-Thru Plugs (LTBP's)

Heyco® Retaining Sealing Washers

Heyco® Retaining Sealing Washers

Heyco® TPE Liquid Tight Hole Plugs, Standard and Low Durometer

Heyco® TPE Liquid Tight Hole Plugs, Standard and Low Durometer

HEYCo-molded™ Liquid Tight Break-Thru Plugs

HEYCo-molded™ Liquid Tight Break-Thru Plugs

No O-Ring Required!

No O-Ring Required!Heyco® Nylon Liquid Tight Threaded Plugs

Heyco® PG Threaded Plugs

Heyco® PG Threaded Plugs

Heyco® Metric Threaded Plugs

Heyco® Metric Threaded Plugs

Heyco® PG and Metric Threaded Plugs

Heyco® PG and Metric Threaded PlugsNickel-Plated Brass

No O-Ring Required!

No O-Ring Required!HEYClean™ Liquid Tight Threaded Vent Plugs

HEYClean™ Liquid Tight Snap-In Vent Plugs

HEYClean™ Liquid Tight Snap-In Vent Plugs

HEYClean® Brass Pressure Equalization and Drain Plugs

HEYClean® Brass Pressure Equalization and Drain Plugs

Heyco® Liquid Tight Cordgrips Installation Instructions for Non-Threaded or Clearance Holes

Heyco® Liquid Tight Cordgrips Installation Instructions for Non-Threaded or Clearance Holes

Heyco® Liquid Tight Cordgrips Installation Instructions for Threaded Mounting Holes

Heyco® Liquid Tight Cordgrips Installation Instructions for Threaded Mounting Holes

Heyco® PG Thread Taps

Heyco® PG Thread Taps

Heyco® PG Hub Liquid Tight Cordgrip DIN 40430 Specifications

Heyco® PG Hub Liquid Tight Cordgrip DIN 40430 Specifications

Heyco® Liquid Tight Cordgrips Torque Chart

Heyco® Liquid Tight Cordgrips Torque Chart

Heyco® Steel Cordgrips Torque Chart

Heyco® Steel Cordgrips Torque Chart

Heyco® Brass Cordgrips Torque Chart

Heyco® Brass Cordgrips Torque Chart

Heyco® Aluminum Cordgrips Torque Chart

Heyco® Aluminum Cordgrips Torque Chart

Heyco® Liquid Tight Cordgrips LabKit #8 (Part #3297)

Heyco® Liquid Tight Cordgrips LabKit #8 (Part #3297)

Labkits

Heyco® Core Products Kit

Heyco® Core Products Kit